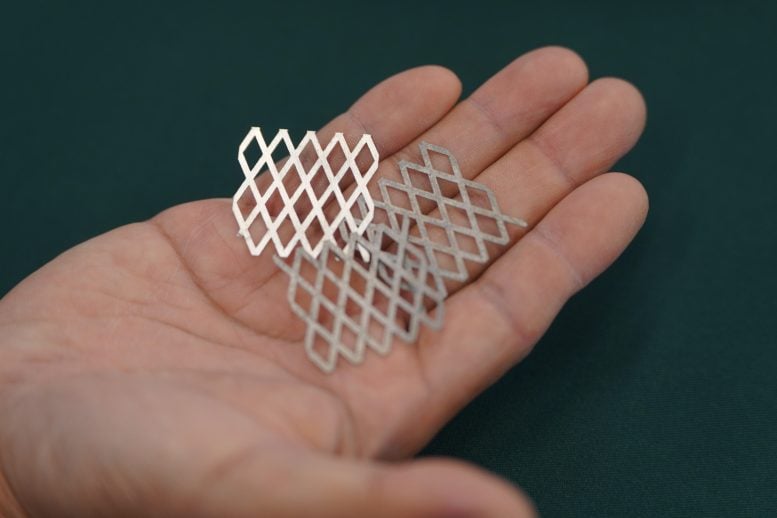

Scientists have developed an innovative stainless steel, SS-H2, for hydrogen production that offers superior corrosion resistance and cost-effectiveness compared to titanium. The discovery could significantly reduce material costs in water electrolysers, paving the way for more affordable hydrogen production from renewable sources. Above is a novel stainless steel for hydrogen developed by the team. Credit: University of Hong Kong

A team led by Professor Mingxin Huang from the University of Hong Kong's Department of Mechanical Engineering has made significant progress in the field of stainless steel. This latest innovation focuses on the development of a stainless steel designed for hydrogen applications called SS-H.2.

The achievement is part of Professor Huang's ongoing 'Super Steel' project, which has previously achieved significant milestones by developing anti-resistance.COVID-19 Development of stainless steel in 2021 and ultra-strong and ultra-tough super steel in 2017 and 2020.

The new steel developed by the team exhibits high corrosion resistance, enabling its potential use for green hydrogen production from seawater, where a new sustainable solution is still in the pipeline.

The new steel's performance in a saltwater electrolyzer is comparable to current industrial practice for producing hydrogen from desalinated seawater using titanium as building blocks. acidThe cost of new steel is very cheap.

The findings have been published in the journal Products today. Research achievements are currently being applied for patents in several countries, two of which have already been granted approval.

Revolutionizes corrosion resistance

Since its invention a century ago, stainless steel has always been an important material widely used in corrosive environments. Chromium is an important element in establishing the corrosion resistance of stainless steel. The passive film is formed by oxidation of chromium (Cr) and protects stainless steel in the natural environment. Unfortunately, this conventional single-pass mechanism based on Cr has stopped further development of stainless steel. due to further oxidation of stable Cr2oh3 As soluble Cr(VI). speciesTranspassive corrosion inevitably occurs in conventional stainless steel at ~1000 mV (saturated calomel electrode, SCE), which is below the potential required for water oxidation at ~1600 mV.

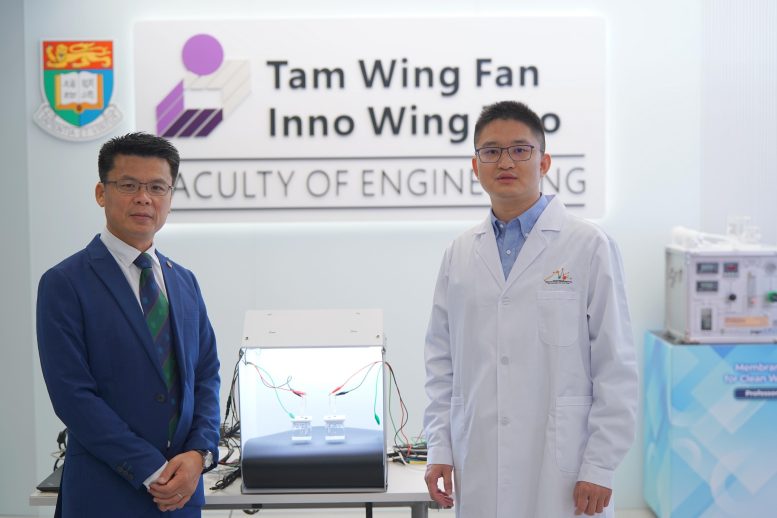

Prof. Mingxin Huang and Dr. Kaiping Yu. Credit: University of Hong Kong

For example, 254SMO super stainless steel is a benchmark among Cr-based corrosion-resistant alloys and has excellent pitting resistance in seawater; However, transpassive corrosion limits its use at higher capacities.

Professor Huang's research group developed a novel SS-H using the „continuous dual passive” strategy.2 With high corrosion resistance. In addition to the single CR2oh3-based passive layer, a secondary Mn-based layer forms on the previous Cr-based layer at ~720 mV. A sequential dual-processing mechanism prevents SS-H2 from corrosion in chloride media to ultra-high potentials of 1700 mV. SS-H2 Demonstrates a fundamental improvement over conventional stainless steel.

Unexpected discovery and potential applications

„Initially, we didn't believe it because it is well established that Mn affects the corrosion resistance of stainless steel. Mn-based passivation is a counter-intuitive finding that cannot be explained by current knowledge in corrosion science. However, when several atomic-level results were presented, We were convinced. Beyond being surprised, we can't wait to use the mechanism,” said Dr. Kaiping Yu, first author of the paper, whose PhD is supervised by Professor Huang.

From the initial discovery of the innovative stainless steel to achieving a breakthrough in scientific understanding, and finally preparing for official launch and its industrial use, the team devoted almost six years to the work.

„Different from the current corrosion community, which focuses mainly on resistance to natural forces, we specialize in developing high-potential-resistant alloys. Our strategy transcends the basic limitation of conventional stainless steel and establishes a precedent. composition Matching development in higher skills. This progress is exciting and brings new applications. Professor Huang said.

Currently, aqueous electrolytes in desalted seawater or acidic solutions require expensive Au- or Pt-coated Ti for structural components. For example, the total cost of a 10-MW PEM electrolysis tank system in its current state is approximately HK$17.8 million, with structural components contributing up to 53% of the overall cost. Professor Huang's group's breakthrough makes it possible to replace these expensive structural components with more economical steel. As estimated, employment of SS-H2 It is expected to reduce the cost of construction materials by about 40 times, which proves the great perspective of industrial applications.

„From experimental materials to actual products such as meshes and foams for hydroelectrolytes, there are still challenging tasks at hand. Currently, we have taken a big step towards industrialization. Tons of SS-H2-based wires have been produced in collaboration with a factory from the mainland. The more economical SS- We are making progress in using H2 in hydrogen production from renewable sources,” Professor Huang added.

Reference: Kaiping Yu, Shihui Feng, Zhao Ding, Meng Gu, Peng Yu, and Mingxin Huang, 19 August 2023, “Continued Dual Passivation Strategy for Designing Stainless Steel Applied Above Water Oxidation” Products today.

DOI: 10.1016/j.mattod.2023.07.022

„Oddany rozwiązywacz problemów. Przyjazny hipsterom praktykant bekonu. Miłośnik kawy. Nieuleczalny introwertyk. Student.