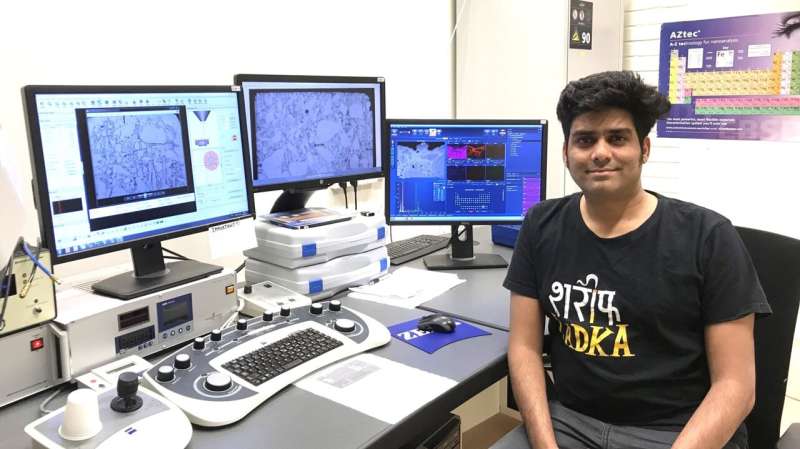

In his doctoral research, Naresh Kumar Wagri examines how lime kilns are affected when burning biofuels. Credit: Charlie Ma

To reduce carbon emissions from lime kilns, there is increasing interest in introducing bio-based fuels as alternatives to fossil fuels. Naresh Kumar Vagri, Department of Applied Physics and Electronics at Umeå University, shows in his thesis that biofuels present challenges due to their diverse chemical and physical properties.

„The penetration of ash sludge that settles on the inner walls of the furnace is much more extensive from biomass than from coal fuel due to the different chemistry of the fuel,” he explains.

In industrial furnaces, boilers and incinerators where high temperature processes take place, an inner shell is required to protect against high temperatures and chemical attack. These linings are usually made of bricks of ceramic materials that can withstand high temperatures. Typical industries where these refractory liners are used are metallurgy, quicklime production, cement production, glass production, and the petroleum and energy sectors.

One problem is that high temperatures and chemical reactions in some industrial processes cause the inert materials to decompose. If molten fuel enters refractory stations through ash holes and small cracks, corrosion can occur. As the ineffective material wears out, the lining must be replaced, thus shutting down the entire process for several days. These stoppages result in production losses and costly maintenance, including new lining materials.

Limestone is burned in lime kilns at temperatures of 1,000°C. Naresh Kumar Wagri in his paper examines how biomass conversion affects the lining material in lime production kilns. The overall aim of the research is to develop knowledge about what happens to waste materials in lime kilns when fossil fuels are replaced by renewable fuels.

Biomass fuels can come from biomass-based waste streams from industries or are grown specifically for burning. However, the ash content and properties of bio-based fuels can be problematic from an ash chemistry perspective. Therefore, before introducing a new fuel source, it is important to investigate its potential effects on furnace lining material.

Kumar Vagri’s results show that ash slag penetrates the coating material, alters the microstructure of the refractory material, and causes degradation. The problem is more widespread than using coal fuel because of the different chemistry of the fuel.

„The next step could be extending to other types of biofuels and other qualities of refractories,” he says.

More information:

Evaluation of bio-based fuel ash effects on magnesia refractory materials in quicklime production kilns. umu.diva-portal.org/smash/get/ … 12372/FULLTEXT01.pdf

QuotationRetrieved 8 December 2023 from : https://phys.org/news/2023-12-corrosion-lime-kilns-biofuel.html (2023, 8 December) Researcher provides better understanding of corrosion in lime kilns fired by biofuel.

This document is subject to copyright. No part may be reproduced without written permission except for any reasonable manipulation for the purpose of personal study or research. Content is provided for informational purposes only.

„Oddany rozwiązywacz problemów. Przyjazny hipsterom praktykant bekonu. Miłośnik kawy. Nieuleczalny introwertyk. Student.