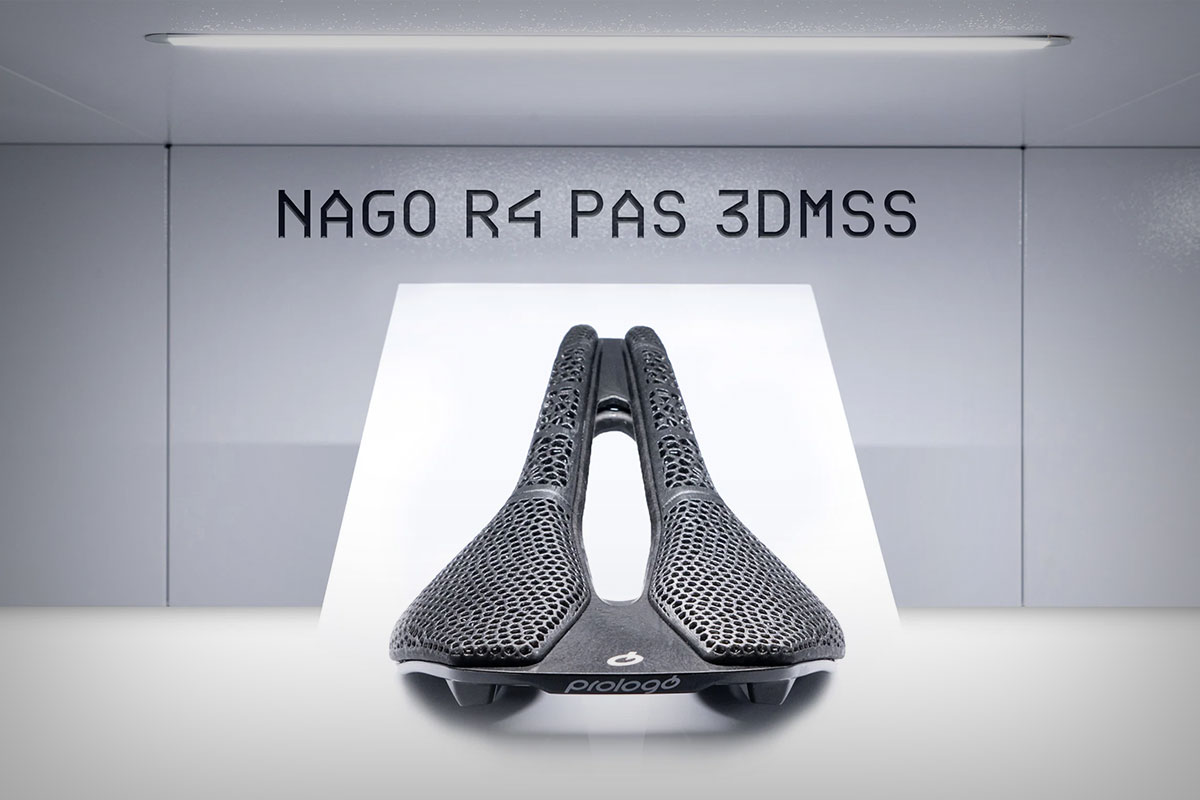

Following the introduction of the first saddles with CPC technology in 2013, characterized by three-dimensional conical nanostructures that improved grip and improved vibration absorption, Prologo takes this technology to a new level with the Nago R4 PAS 3DMSS, an innovative 3D developed from the new ultralight saddle pressure test analysis. Printed multi-sector card.

The lightest 3D printed harness on the market

The Prologo Nago R4 PAS 3DMSS retains the same ergonomic T shape and compact dimensions (245×137 mm) of the Nago R4, its versatile saddle that has been adopted by Tadej Pogacar, Mark Cavendish, Geraint Thomas, Pello Bilbao and Alberto Bettiol as well as professional cyclists.

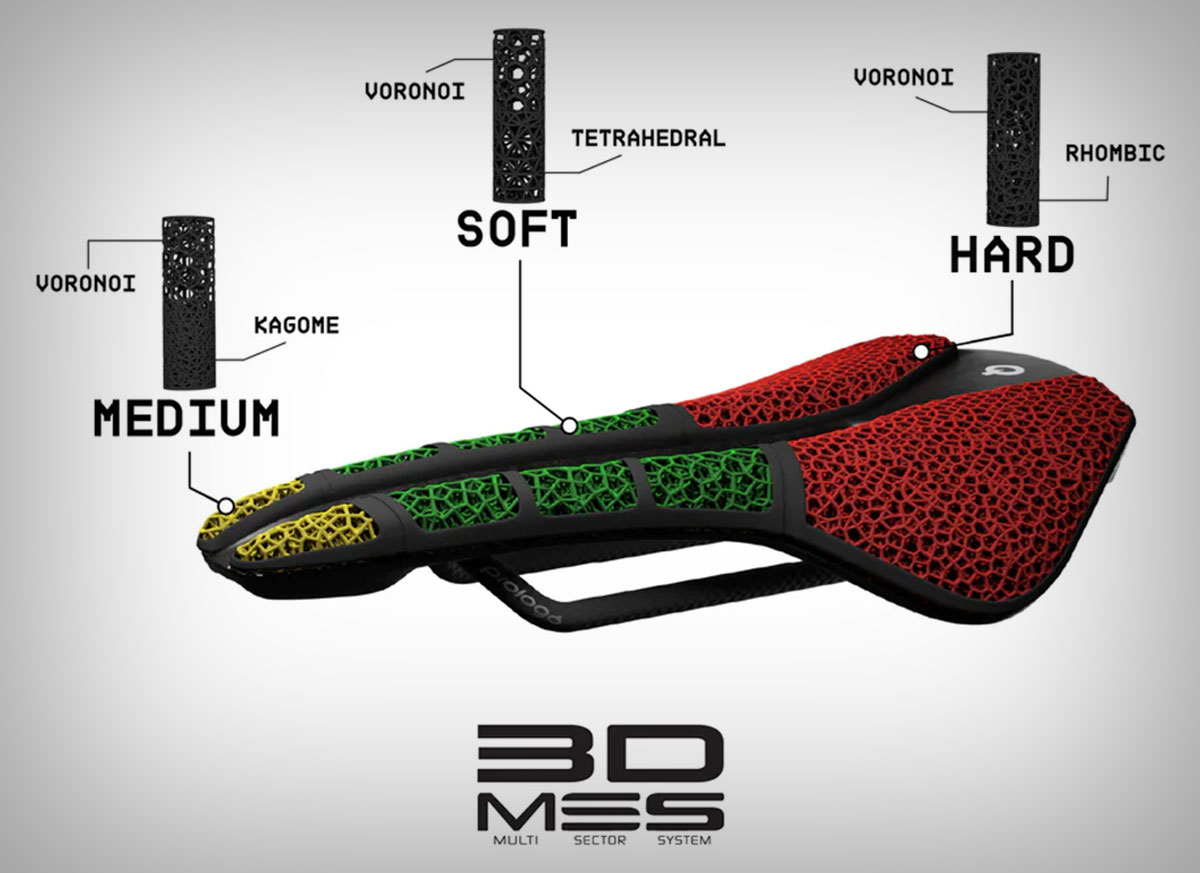

This new model pressure map was born from the evaluation of MyOwn tests, a Prologo system that allows the scientific analysis of the pressure areas exerted on the saddle by professional and amateur cyclists. The data collected guided the creation of a very light 3D printed saddle, made of separate sections, that adapts well to different pressure areas, guaranteeing maximum support and comfort during pedaling.

The cover of the NAGO R4 PAS 3DMSS combines MSS – Multi Sector System technology with an innovative 3D printing process that allows the creation of five separate sectors for each side of the saddle. .

Each sector has complex geometries, variable densities and different elastic coefficients, adapted to its specific function:

- The back area, with its high density and elastic coefficient, provides more support to the ischial bones.

- The three intermediate sections have a low density and a medium elastic coefficient to provide maximum comfort for soft tissue.

- The front part has a medium density and a low elastic coefficient for good support when pedaling at the tip of the saddle.

Of course, ProLogo has paid special attention to the weight of the saddle, which is usually higher in 3D produced models. Using Pressure Map MyOwn test data, the brand identifies low-pressure areas and restricts materials used in those areas without sacrificing comfort or performance.

With an injected carbon base and the brand's renowned carbon, aluminum and Kevlar knock rails, the new Nago R4 PAS 3DMSS weighs just 149 grams, the lightest of all 3D printed saddles on the market. The saddle will be available from April on the Prologo website and at regular outlets for an announced price of €420.